3D Printers and Additive Manufacturing Applications

Additive manufacturing or more popularly referred to as 3-D printing, involves making three dimensional objects using digital files. Additive processes are used in the development of 3 dimensional printed objects. This means several layers are laid out until the desired object is finally developed. Generally, layers are rendered as thin slices of horizontal cross-sections of the desired object.

The entire process starts with the development of a virtual design. Computer-aided design software is used in modeling the 3-D object. 3-D scanners are also used, specifically for copying existing objects. Three dimensional digital copies of objects are obtained through 3-D scanners, which are then rendered on three dimensional modeling programs. If you click this page, you’ll learn more about this technology.

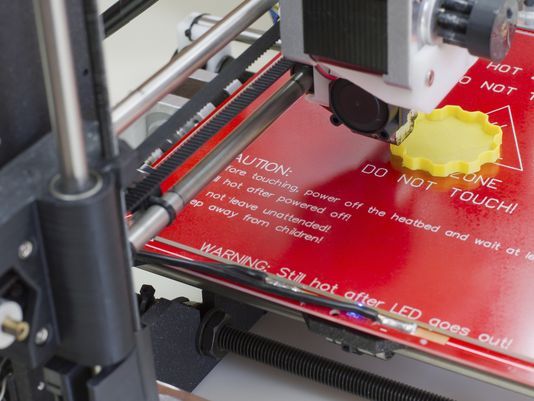

A 3-D printer is used in making hard copies of the digital files. In preparation for printing, the final model is sliced into several sections using a computer program. Once uploaded into the printer, the object is printed out layer after layer. Each slice is read and processed so a print out of the final model can be obtained. You know you have a good 3D printer if the final output does not show any sign of visible layering.

More recently, 3-D printing technology has become a household term. More updated information about 3D printing can be read at http://edition.cnn.com/2012/07/20/tech/3d-printing-manufacturing-technology/. Nevertheless, several people still do not quite understand what this really entails. What most people are not aware of is that this technology has been widely in use in the industrial sector for several decades already. Manufacturers have been using this technology for decades in designing prototypes for their products. This is what manufacturers refer to as rapid prototyping.

Investing on a three dimensional printer can require several thousands of dollars. In spite of this large initial investment, significant savings can be realized in the long run. Manufacturers need to develop several prototypes for a single product. With the help of an industrial stratasys reseller 3D printer, manufacturers no longer need to spend thousands of dollars to develop a single prototype, and no longer do they need to spend several weeks on manually putting all the layers together. They can instantly print out the desired prototype with the help of the right technology, right when they need it.

Three dimensional printers are also used in rapid manufacturing. This new kind of manufacturing process involves the use of three dimensional printers in short-term custom manufacturing. This means printed objects are not merely prototypes. They now become the actual finished product. With the help of this new type of industrial printers, we can look forward to the availability of more personalized products.